Industrial printing market is moving through a revolutionary phase led by one-pass UV advances. This innovative system allows rapid throughput with outstanding image quality and robustness. With instant ultraviolet curing of inks and coatings, single-run UV printing avoids slow drying and repeat passes, lowering production expense and duration.A key plus is achieving striking, durable prints across a broad substrate mix such as plastics, metals, and textiles. Top-tier resolution in single-pass UV generates precise image and typographic detail, excellent for packaging, signage, and marketing items. Furthermore, this eco-friendly technology utilizes lower energy consumption compared to traditional printing methods, contributing to a more sustainable production process.

Industrial printing market is moving through a revolutionary phase led by one-pass UV advances. This innovative system allows rapid throughput with outstanding image quality and robustness. With instant ultraviolet curing of inks and coatings, single-run UV printing avoids slow drying and repeat passes, lowering production expense and duration.A key plus is achieving striking, durable prints across a broad substrate mix such as plastics, metals, and textiles. Top-tier resolution in single-pass UV generates precise image and typographic detail, excellent for packaging, signage, and marketing items. Furthermore, this eco-friendly technology utilizes lower energy consumption compared to traditional printing methods, contributing to a more sustainable production process. Embedding single-pass UV into operations opens up additional options for businesses wanting better print outcomes.

Embedding single-pass UV into operations opens up additional options for businesses wanting better print outcomes. Single-Pass UV Trends

High-speed digital printing has always sought efficiency. Conventionally this meant repeated ink passes, causing longer production times and alignment issues. Nevertheless, Single-Pass UV’s emergence is reshaping the field. This innovative technology uses ultraviolet light to instantly cure inks in a single pass, resulting in dramatic improvements in speed and precision.Single-Pass UV creates striking color fidelity with high clarity and detailed richness. So it’s ideal for applications including bulk packaging, signage, and promotional prints that require speed and strong visuals. As the field advances, single-pass UV should yield more remarkable improvements for high-speed, versatile, and cost-efficient printing.

Single-Pass UV Printers: Redefining Productivity

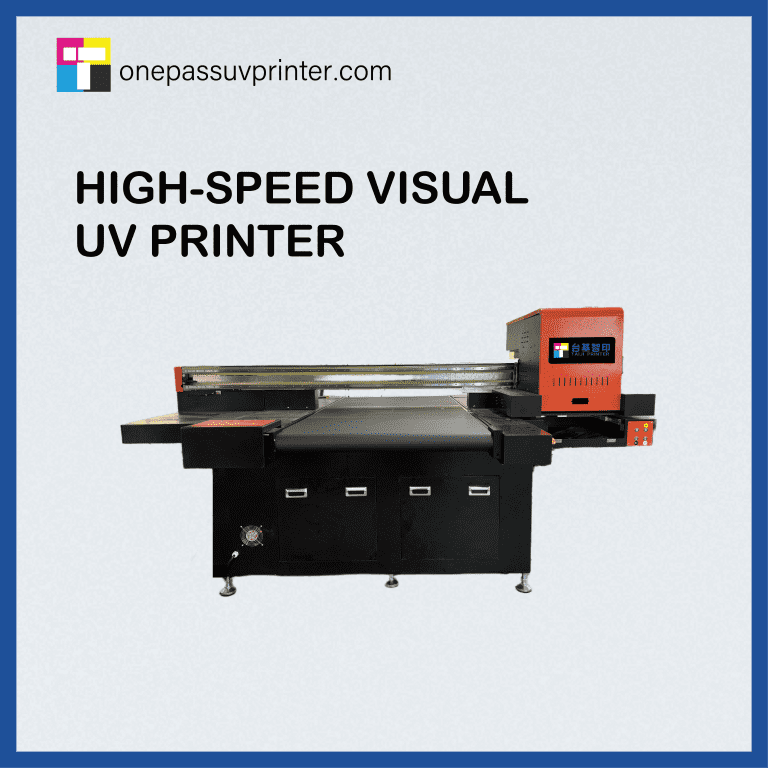

In modern printing tech, single-pass UV printers are revolutionizing how speed, precision, and efficiency are delivered. These devices harness ultraviolet curing to set inks rapidly, enabling very high production rates. Their single-pass multi-color output results in top-tier resolution and vivid color accuracy. From personalized items to large commercial print jobs, these printers handle numerous applications to meet growing customer expectations.Reimagine Your Print Operations

Expect to be impressed by the single-pass UV printer — a strong solution transforming industry norms. This cutting-edge device harnesses ultraviolet light to cure inks in one pass, providing excellent print clarity and resolution.- Benefit from bright tones with exceptional detail

- Increase production velocity with rapid print tech

- Explore diverse creative uses with multiple printable surfaces

Fast-Track UV Printing: Delivering Unmatched Efficiency

UV printing reshaped the graphics industry by delivering rapid throughput, refined precision, and bright colors. Yet express UV printing heightens these benefits, delivering remarkable manufacturing efficiency. This method uses tailored printers that generate high-resolution prints at impressive speeds. With near-instant curing and minimal drying, speedy UV printing enhances workflows enabling easy completion of demanding jobs. Benefits from rapid UV printing also include quality and versatility beyond pure efficiency. It achieves remarkable print excellence, resilience, and suitability for many applications. From product packaging to banner production and label runs to marketing signage, high-speed UV changes operations so businesses can adapt and lead.

Rapid Printing: The Ultimate Solution for Fast Turnaround Times

In a time-driven market, speed is crucial. Regarding print, firms need systems delivering quick, effective output. This is the promise of One-Pass Print. The technology enables printing in one pass, removing multiple runs and cutting processing duration. With One-Pass Print, you can enjoy significantly faster turnaround times, freeing one pass printer up your valuable time and resources. So, businesses large and small can take advantage of One-Pass Print’s merits. From creating marketing materials to producing essential documents, this technology empowers you to print what you need, when you need it, without compromise.Single Pass UV: Where Quality Meets Velocity

In modern production ecosystems, efficiency is the key priority. Producers need systems that preserve quality and sustain speed. Single-pass UV surfaces as a pioneering solution tying high-quality inspection to quick curing. This process uses immediate UV curing of inks and coatings to produce vivid durable finishes while shortening production time. The precision of single-pass UV guarantees flawless output meeting the most rigorous standards. The benefits extend beyond enhanced quality and speed. Single Pass UV reduces waste by eliminating the need for lengthy drying times, contributing to a more sustainable production process.- Additionally, Single-Pass UV’s adaptability supports industries ranging from packaging and graphics to electronic assembly.

Transforming Digital Printing Through High-Speed UV

The sector progresses continually, driven by persistent demands for speed, precision, and innovation. Rapid UV tech has surfaced as a transformative force combining these crucial elements. The instant ink curing of UV printing eradicates long drying times and broadens the scope of printing applications. This fast curing mechanism supports superior print speeds, markedly reducing production time and enhancing efficiency. Additionally, UV inks show great durability and resistance to fade, abrasion, and moisture, suiting many uses. From vivid signage to rugged packaging, high-speed UV changes conventional printing methods.- Pros

Instant Print Era: One-Pass UV In Practice

Across graphics and design industries, time is a scarce commodity. Customers require fast delivery times while businesses must supply top-quality prints on demand. One-pass UV printers address this need by providing an innovative solution for modern printing. These high-tech printers use UV inks that fix instantly with light, obviating slow drying processes. Result: immediate prints showcasing lively colors and robust finishes. Therefore, one-pass UV printers gain traction across a range of sectors. From retail and e-commerce marketing to photography, fine art, and manufacturing, organizations use instant printing. Applications include creating personalized products, producing custom signage, and generating eye-catching marketing materials. The perks stretch beyond speed and workflow improvements. Single-pass UV printers ensure accurate color, fine resolution, and substrate flexibility for rigorous projects.- Also, one-pass UV offers environmental benefits by not requiring harsh solvents or VOCs.

- In short, instant prints are now mainstream; single-pass UV brings speed, adaptability, and quality that reconfigure printing for efficiency.

Streamline Production with Single-Pass UV

Refine operations and achieve new efficiency gains with a single-pass UV printer. This state-of-the-art tech prints vivid, high-resolution imagery onto various substrates in a single pass, eliminating multi-layer workflows.- Secure extraordinary speed and decrease production time.

- Enhance production output with reduced turnaround.

- Use UV ink’s durable precision to secure long-lasting vibrant prints.

Single-Pass UV: A Game-Changer for High-Impact Printing

Single-pass UV printing is now recognized as a breakthrough for high-impact applications. Using UV to cure ink instantly, this method brings significant advantages beyond traditional processes. Primarily, single-pass UV delivers unmatched image fidelity with vivid colors and sharp detail. Eliminating drying time through UV curing raises productivity and shortens turnaround.- Furthermore, prints from single-pass UV show high durability and protection against fading and abrasion.

- All told, great image quality, boosted productivity, and durability make single-pass UV a persuasive choice for impactful printing.